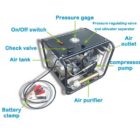

Hookah Compressor Diving Electric SCU80P

Hookah compressor electric system with 2 hoses connector.

SCU80P - COMPRESSOR HOOKAH ELECTROC SYSTEM (2 ADAPTER HOSE)

GARANSI 3 BULAN - KERUSAKAN PABRIK (BUKAN KERUSAKAN KARENA SALAH PEMAKAIAN)

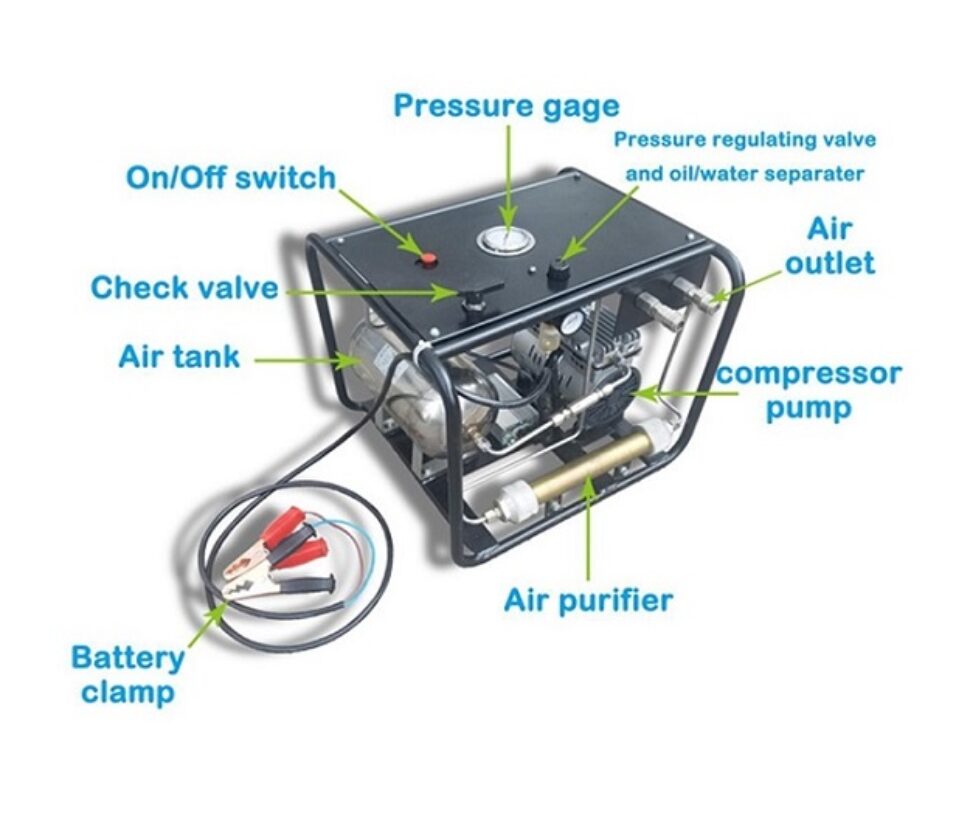

HOOKAH DIVING COMPRESSOR ACCU SYSTEM

- Use Accu 12v 100ah = 2 hours / 2 person.

- Working without using any oil

- All the spare part is ready in stock

- Two output air breathing (2 person)

Include / Termasuk:

- 1x 2nd stage octopus + Black hose

- 1x Repair kit

Exclude / Tidak Termasuk:

- Diving Mask

- Accu 12v 100ah

SAFETY CAUTIONS

Please read this operation manual carefully before installation and operation

This series are high pressure air compressor. It compresses atmosphere air go to pressure 0.3/0.8Mpa, 45/110psi, after be purified and separated by the filter and separator.

It discharge clean air accords to GB18435-2001 breathing air standard. It is widely be used for breathing of diving and fire fighting; paintball PCP shooting and other high pressure filed industries by its reliability, durability and portability.

Products range :

- DC 12V

- AC 110V 220V

- Gas engine driven

- Optional accessories : diving hose and musk

- Check the electric voltage in nameplate is same as your local electric supply

- Check the lubricate oil has been put in before running

- Increase rated pressure setting is forbidden

- There is potential danger of pipe burst or connect fitting blow off under high pressure, please avoid body too near compressor when it running

- if there are no auto stop function, don't leave compressor until it reach rated pressure and shut down it by manual

TECHNICAL DATA

SCU80 /LM80/ DC 12V diving air compressor

- Charging Rate: 60-100L/min; 2-3cfm

- Suction pressure: atmosphere

- Working pressure: 0.8MPa, 8bar, 110psi

- Media: air

- No.of stage and cylinder: 1

- DC power: 550W/12V

- Cooling: air

- Driven: direct driven with DC motor

- Shout down:Automatic stop by pressure switch

- Pressure indicate:Gauge

- Protection :Safety valve in outlet

- Filtration:water separator and breathing filter

- Lubricant: oil free, no lube oil

- Dimension:500 X 450 X 450mm

- Weight:25kg

- Noise:Less than 45 dB(A)

- Receiver tank: 10 liters stainless steel

- Outlet : 2 ports

STRUCTURE

Working process

Atmosphere air is sucked into cylinder of the compressor, and compressed to reach 0.3Mpa/0.8MPa 40/110 psi pressure, through regulator with water separator , then purified by filter. Discharge clean air for diving breathing.

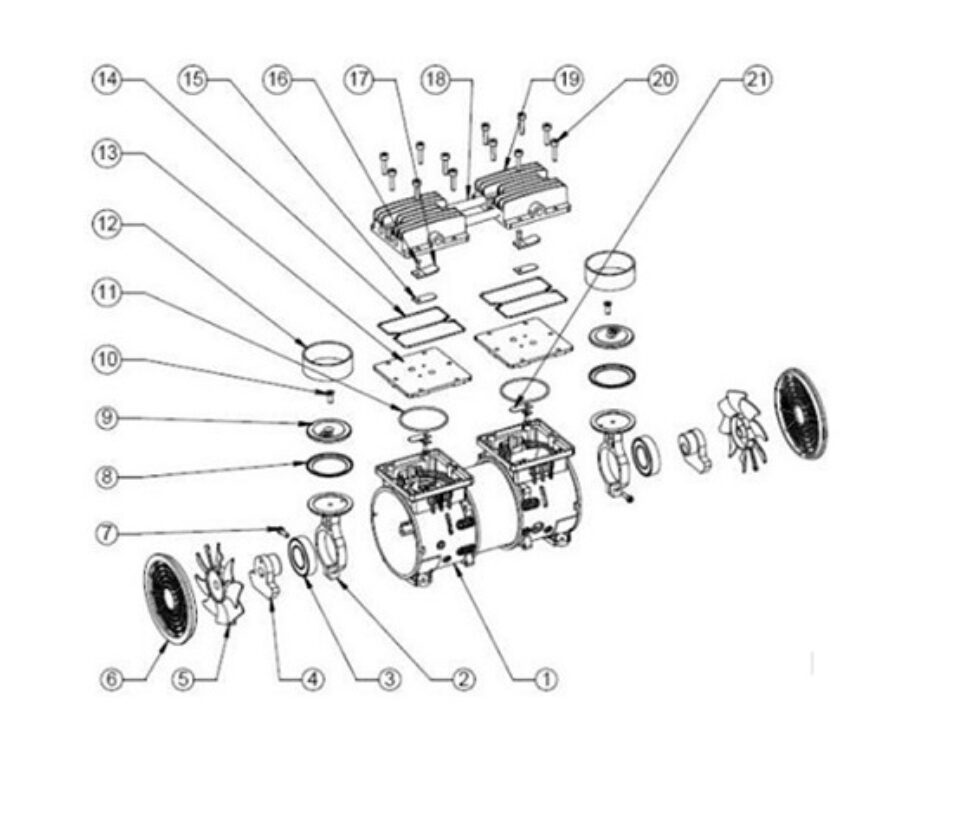

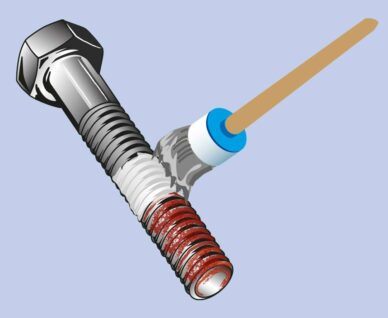

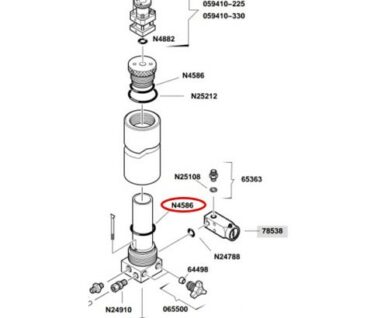

Pump unit

The pump block unit is composed of crankcase, crankshaft, cylinder, piston, intake and discharge valves, connect rod , bearing etc.

It is oil-free, non lubrication, direct driven type compressor.

| Part number | Part name | quantity |

| 001 | Pump body | 1 |

| 002 | Connect rod | 2 |

| 003 | Eccentric wheel bearing | 2 |

| 004 | Eccentric wheel kit | 2 |

| 005 | Cooling fan | 2 |

| 006 | Cooling fan cover | 2 |

| 007 | screw | 2 |

| 008 | Piston bowl ring | 2 |

| 009 | Press plate | 2 |

| 010 | screw | 2 |

| 011 | Cylinder seal | 2 |

| 012 | cylinder | 2 |

| 013 | Valve plate | 2 |

| 014 | Cylinder cover gasket | 2 |

| 015 | Discharge valve plate | 2 |

| 016 | screw | 2 |

| 017 | Limited position kit | 2 |

| 018 | Connect hose | 2 |

| 019 | Cylinder cover | 2 |

| 020 | screw | 12 |

| 021 | Intake valve plate | 2 |

Maintain schedule

- 008 009 010 011 012 013 014 015 021 are consumable parts, regular it every 1year or 2000 hours. Time will be shorter if use compressor near the sea.

Gauge & safety valve

The pressure gauge is installed in final stage of the compressor to display discharge pressure.

The safety valve is installed at the place of discharge to take the overpressure protection. If the discharge pressure is higher than preset value, the safety valve will open and release pressure.

Note: do not adjust the safety valve, otherwise it will result in serious damage

Pressure switch

The compressors are preset rated working pressure as per order . The compressor will stop automatically when pressure reach rated pressure. And re-start compressor when pressure is lower than minimum.

Note: don’t try to adjust it if not get authorized

- Electric starter

- Press ON/OFF red button on pressure switch to start compressor.

- Drain valve

- Open valve under receiver tank to drain moisture water in tank.

INSTALL AND OPERATION

Installation

The compressor must be mounted on a firm, level base Where is with well-ventilated and rain-proof , non-hazardous locations. The environment temperature is d to be lower than 40 degree C.

Check before running

Pressure switch check

- pressure switch must be in position “ OFF” (STOP)

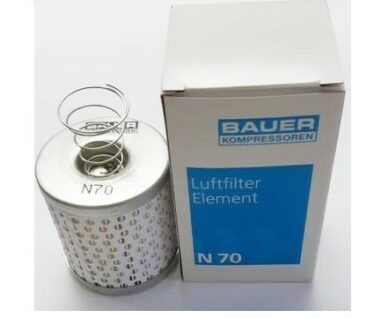

- Intake air filter check

- install intake air filter on pump block

Running

- Connect electric cable to DC power supply (12V ONLY) DC battery: 12V ; Power connection : red color wire/clamp to + (positive pole) / black color wire/clamp to - (negative pole

- Connect air hose to discharge outlet port with fast plug in coupling

- Open discharge check valve

- Close drain valve under air tank

- Press ON bottom in pressure switch to start compressor

- Compressor will download automatically when reach rated pressure ( presetting unload pressure is 0.8Mpa/ 8bar/ 110psi), and load again when pressure drop down to minimum pressure ( presetting load pressure is 0.5Mpa/ 5bar/ 75psi)

- Turn around regulator to make discharge pressure go through air hose to suitable for mask breathe.

- Press OFF bottom in pressure switch to stop compressor when finish work

Note: Compressor is oil-free type, don't need any lubricate oil to take in

MAINTENANCE

Intake filter element (No.022) and part NO. 008 009 010 011 012 013 014 015 021 are consumable parts,

regular it every 1year or 2000 hours. Time will be shorter if use compressor near the sea.

| 1000 h | Annually or 2000hrs | |||

| Intake air filter element | ◆ | |||

| Piston bowl ring | ◆ | |||

| Press plate | ◆ | |||

| screw | ◆ | |||

| Cylinder seal | ◆ | |||

| cylinder | ◆ | |||

| Valve plate | ◆ | |||

| Cylinder cover gasket | ◆ | |||

| Discharge valve plate | ◆ | |||

| Intake valve plate | ◆ |

△ Check ◆

5.1 lubricate oil

Oil free type, don't need lube oil

5.2 air filter

blow air filter by compressed air to clean dust.

The air filter element must be changed every 2000 working hours or annually.

5.3 Filtration for breathing air (ACTIVE CARBON FILTER)

The outlet air purification depends on the activated carbon and molecular sieve, so filter elements must be d periodically, especially for breathe purpose. Follow are advice interval time.

| Ambient temperature(℃) | Capacity(L)× Number | Time for change(hour) |

| 40 | 6×55 | 10 |

| 30 | 6×100 | 18 |

| 20 | 6×160 | 30 |

| 10 | 6×300 | 55 |

| 5 | 6×400 | 75 |

| 0 | 6×600 | 110 |

Note: Filter elements must be d at once if people feel particular smell.

Replacement: open the filter cover; the active carbon in bottle

TROUBLESHOOTING

| Fault Reason | Over low P | Over high P | Over noise | Over heat | Not start | Air leak |

| Pressure switch damage | √ | √ | ||||

| Motor capacitor damage | √ | |||||

| safety valve damage | √ | √ | √ | |||

| drain valve damage | √ | √ | ||||

| Discharge valve damage | √ | √ | √ | |||

| Piston ring damage | √ | √ | ||||

| protector shut off | √ | |||||

| foot damage | √ | |||||

| Solenoid valve damage | √ | √ | ||||

| One way valve damage | √ | √ | ||||

| DC/AC power too low | √ | √ | ||||

| intake filter block | √ | |||||

| In/out valve damage | √ | √ |

Note : Rekomendasi dari pemerintah digunakan untuk kedalaman maksimal 5 meter

| Category | : | Compressors |

| Brand | : | Zeepro |

| Code | : | |

| SKU | : | 9931 |

| Stock | : | Ready |

No product attachment available